This is just an aid-memoire regarding how to change filament on a Creality Ender 3 3D printer.

Changing/reloading the filament is pretty straightforward. But I know from personal experience that there are a couple of minor snags/irritants that can occur due to “economies” in the design of the Ender 3. Though it has to be said that for the money the Ender 3 is really good value. The latest version (far better than mine!) is here on Amazon.

Removing Existing filament.

Assuming the filament has not snapped in the Bowden tube then removing it is easy. Turn on the Ender 3 go to “Prepare” on the display then scroll down to either pre-heat PLA or pre-heat ABS. Select the one that is appropriate. (see more later in the post if you are using something a little more exotic like TPU). Then select “Preheat PLA/ABS End” There is no need to heat the bed up.

The pre-heat PLA on my machine raised the print head temperature to 190 degrees centigrade whereas the pre-heat ABS raises it to 240 degrees centigrade.

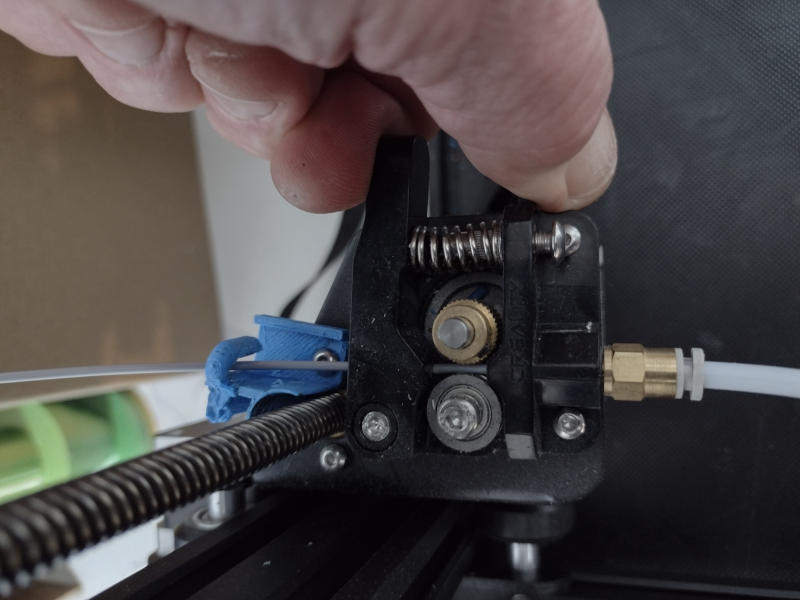

When the print head reaches temperature the filament can simply be pulled out. You need to pinch the spring clip on the entry feed to the Bowden tube so to release the pressure on the filament. Then with the other hand pull out the filament.

That’s it! This will obviously leave a small amount of filament in the print head. If you are going to use the same type of filament then imho the best thing to do is feed it in now. Use it to “push out” the last of the old batch. Which brings us to the first of my irritants with the Ender 3.

Feeding in new filament.

In an ideal world all you have to do is remove the old roll of filament from the hanger, put the new roll on it then push the filament in through the nozzle entry, through the spring clip, down the Bowden tube and into the print head.

But for me that rarely happens. The spring clip on the entry to the Bowden tube misaligns the filament and I (personally) have a devil of a job getting the damn thing into the Bowden tube. It is one of those jobs that needs three hands.

- One to operate the spring clip

- One to push the filament through

- One (with a blade/spatula or whatever) to line the filament up with the entry to the Bowden tube so it goes in.

Sometimes I find that even when you get this far the filament then fouls on the entry to the Bowden tube!

My work round for not having three hands goes something like this.

I remove the Bowden tube from the feeder motor assembly. I do this by pushing the white ring in and then simply pull it out.

Then from the reverse side I feed in a small length (say 6 inches long) of filament and into the grip of the spring clip. Then I feed the new filament in. I try and snag it against the short piece so the short piece “leads” the new filament in through the entry hole to the Bowden tube.

I suppose you could try hitting it with a soldering iron to join the two together or whatever, but I find that usually with a couple of attempts the short length successfully leads the new filament into the Bowden tube aperture.

When it’s through, I feed it into the Bowden tube and re-insert the Bowden tube into the feeder motor assembly. Then it is just a matter of holding open the spring clip pushing the filament down the Bowden tube into the print head. Keep pushing gently and the new filament will melt and expel the old. You can watch the color change as it comes out. There will only be a few inches of waste.

How to Change the filament type on Ender 3

What if you want to change filament on an Ender 3 from one type to another. Say you wanted to go from using PLA to ABS or vice sa versa. Then there’s two ways to do it. (I’ve done both, but I now prefer the first option which is to change the nozzle).

The first is to change the extruder nozzle for a new one. Or of course, you can change it to one that has previously been used with the new type of filament you are loading. (See this post on how to change nozzle) Nozzles are cheap (see Amazon here) so this really is not going to break the bank if you need to fit a new nozzle when you change material.

But alternatively you can also simply feed in the new filament and displace the old. The only caveat with this is that obviously the filament in the print head has to be molten enough to get pushed out by the new stuff coming in.

If the original filament was ABS (molten from around 220 degC upwards) and you are pushing in PLA, heating the bed to 190 degC (That’s the Ender 3 setting for pre-heating the print head for PLA) is probably not going to get the remaining ABS up to a high enough temperature to allow the PLA to push it out.

But luckily there is a sweet spot where both ABS and PLA are molten. It’s around 220 degC.

So instead of using the “Prepare”→Preheat facility, go to “Control”→Temperature→nozzle. Wind the print head temperature up to around 220 degC.

When it get up to around there try gently pushing the PLA in and see if the ABS comes out. If it doesn’t then you can up the temperature a little and try again. Or of course, you can always just change the print head. Going the other way (i.e adding new ABS to a print head previously used with PLA) is less fraught as the PLA will be well molten at ABS pre-heat temperature (240 degC). Just use the same method.

Other filament types generally have temperature ranges very similar to PLA so they are less prone to difficulty. Assuming you are feeding them into replace PLA or vice sa versa.

Filament Types and Temperatures.

Here’s a list of rough working temperatures for a range of filament materials I’ve picked up off various places on the internet. Hopefully they are correct but caveat emptor!

3D printing Filament Operating Temperatures

- PLA 200 – 230 degrees Centrigrade

- ABS 230 – 270 degrees Centrigrade

- TPU 205 – 300 degrees Centrigrade

- PETG 220 – 250 degrees Centrigrade

- PLA+ 210 – 235 degrees Centrigrade

These filament types all have different niches. But in many cases they also overlap for general use. I feel it is worth having a selection rather than just staying with PLA. Here’s the SunLU page on Amazon that gives a brief description of each filament type. Another Amazon supplier with a good range of both types and colors is Duramic 3D on this link.

Filaments generally tend to start going “runny” about 10 degrees below their minimum working temperature. So if you are pushing one out with another choose a temperature sweet spot that suits both.

But what if the Filament snapped in Bowden Tube?

So how do you change the filament on an Ender 3 when the filament has somehow broken in the filament tube? So that after pulling it out you leave a few inches in the tube at the bottom which blocks it?

You have to detach the Bowden tube at the extruder. Push the white ring in and hold it in. Then withdraw the Bowden tube with the other hand. Withdraw the Bowden tube from over the filament. Then when the filament is exposed simply pull it out of the hot print head.

There is a (BIG) warning attached to doing this. Make ABSOLUTELY SURE that when you refit the Bowden tube that it goes right back in as far as it can go. If you leave any space between the Bowden tube and the rear face of the extruder nozzle you seriously risk getting a blockage when you are half way through your next print. Any bit of debris in the print head <may> prevent the Bowden tube fully entering the chamber and butting up to the nozzle.

Personally I’d take the nozzle out and push the Bowden tube right through. This will flush any such debris out (see this post for how and why). But I suppose as long as you are sure that the Bowden tube really has gone all the way back in then you can wing it. If your Bowden tube gets frayed/damaged it is easily and cheaply replaced one example is this link on Amazon Two meters for $7.99 !! That should keep you going for about twenty years!

Anyway, writing up how to change the filament on an Ender 3 has turned out to be a long post. Much longer than I intended frist! But I hope it helps.